AGCO Transmission Facility Completed as Part of Valtra's High-Technology $38M Investment Project

AGCO Corporation (NYSE: AGCO), a global leader in the design, manufacture and distribution of agricultural machinery and precision ag technology, today announced the expansion of Valtra's Suolahti transmission plant has been completed on schedule, bringing with it thousands of square metres of new production space. This major investment modernises production and improves working conditions.

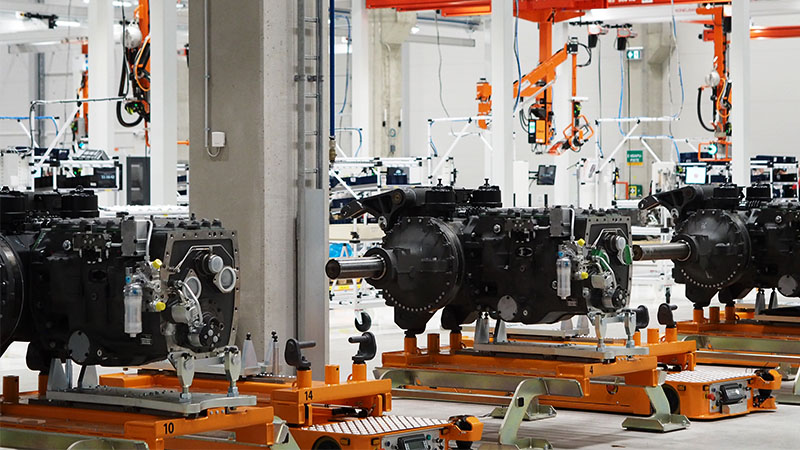

The expansion enables the production of new AGCO Continuously Variable Transmissions (CVT). Currently, the factory produces gearboxes for the Valtra N and T Series tractors and supplies transmissions for the South American market and components for other AGCO production facilities. The introduction of the new Valtra Q and S Series gearbox test bench facilitates the production of higher-performance tractors and meets growing customer demand.

The global expansion project is unique in the scale of the Suolahti plant. The increased production capacity for AGCO CVTs will help meet the growing demand for Valtra and other AGCO brands.

“Our Suolahti plant plays a critical role in AGCO’s global manufacturing network for tractors and components,” said AGCO Senior Vice President, Chief Supply Chain Officer Tim Millwood. “The completion of the CVT expansion in Suolahti enables us to meet the growing demand for not only AGCO CVT’s for Valtra but also AGCO’s other leading brands.”

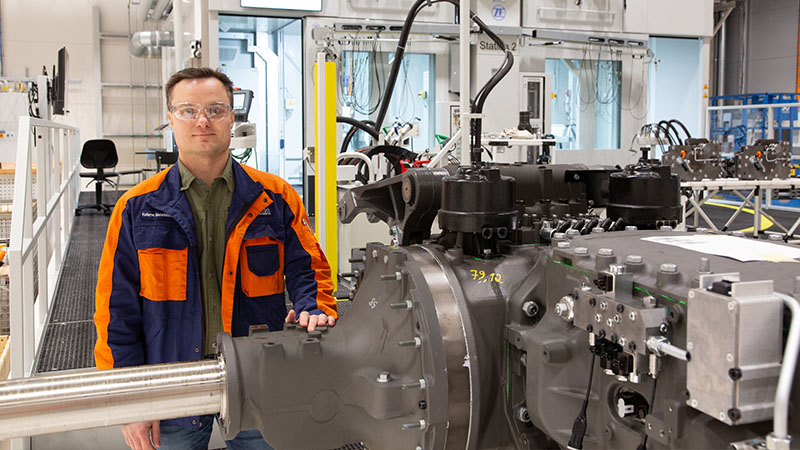

"This investment will allow us to double our transmission capacity and bring new expertise to the Valtra lineup of tractors," says Kullervo Mansikkala, Transmission Plant Manager. “It will also create new jobs in Suolahti. We are improving the safety and working environment for our team through increased automation and precision machining, which will provide a cleaner and quieter workplace."

State-of-the-art technology has been at the heart of the expansion project. The new production facility has been designed using a digital twin, real-time virtual replica of the entire production facility, including machines, processes and workflows - which has enabled the simulation of production efficiency, safety and worker ergonomics. This approach allows production to start directly at the optimum level.